Immersion Heaters

HC Thermal is uniquely positioned in the industry as one of the only global heater companies that fully engineers, designs, and executes the filling (MgO, Sheath, NiCr) of the tubular heaters which is the science and success within every heating system. The tubular heater design can vary for each application based on process conditions, heat transfer, corrosion allowances, and formed the shape of the process.

The Electric Immersion Heater at HC Thermal is entirely generated by electricity, causing all of the energy in the product being heated to be completely consumed. This ensures the high efficiency of the heated product. Typically, electric immersion heaters heat up various liquids and serve almost as a large kettle--by using electricity and metal to heat water or other liquids in a large storage cylinder.

More About This Product

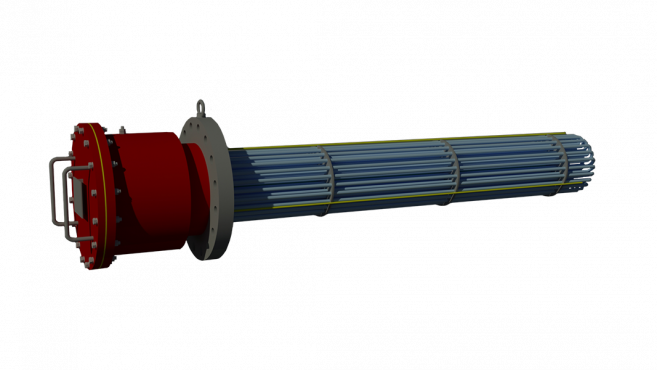

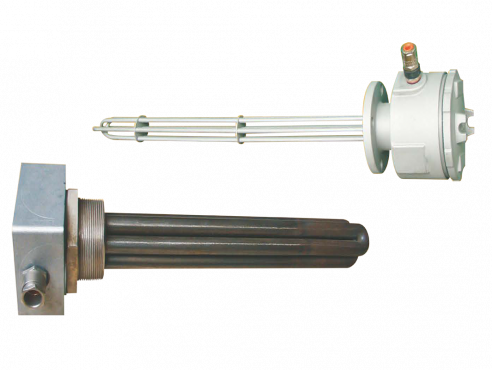

Electric immersion heaters and process immersion heaters are the heart of many of the custom thermal systems HC Thermal provides. The immersion heaters have their own HCT heating elements that are fixed into a flange or plug and then “immersed” into a particular process (ANSI or DIN raised face blind flanges are the most popular). Screw plugs are popular for small applications up to 3 inches and plate material can be used to make many types of heaters including the “Duct” style.

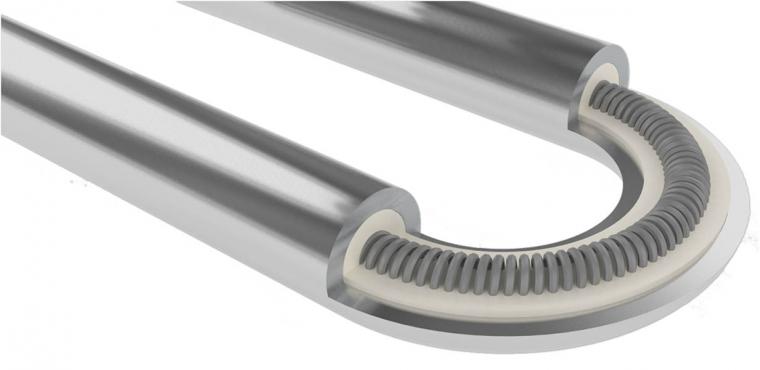

Our Standard Element

Our standard element is a .043 wall thickness tube, a .475” diameter, in 321 stainless steel. We have options for other 300 series stainless, Inconel, and Incoloy. We use a specialty purity blend grade of MgO as our insulation material with NiChrome wire. Our elements are made per process application, so custom options for element cold sections, variable watt densities, voltages, and alloys are easily adaptable. We also have an industry-leading tight-bend radius to be able to maximize element count configurations into a bundle that fits diameter tolerances.

The HC Thermal electric immersion heater has supporting materials such as laser-cut spacers and rods in 300 series stainless and other metal alloys.

Terminal Housing

The terminal housing where the elements are joined together with copper bussing can be either liquid-tight or explosion-proof. We offer several certifications such as CSA, Atex, and FM. Our housings can be made from carbon or stainless steel and offer such features as standoff housing from the flange, to keep housing temperatures down.

HC Thermal also offers ASME U-Stamp and other certifications around the world to meet specifications of the most demanding pressure boundary specification.

HC Thermal engineers and manufacturers electric heaters

HC Thermal engineers and manufacturers electric process immersion heaters to provide a project-driven solution for use throughout all process industries; including Oil & Gas, Chemical/Refining, and Power Generation. Whether immersion or circulation heaters are required, HCT completes a thorough review of the process conditions, which ensures a quality product with a long heater life is delivered.

Capabilities

-

HCT has an optimized solution for use in most process fluids no matter the location and environment.

-

HCT has in-house ASME vessel and fabrication abilities to complete package integration with competitive delivery times.

-

HCT is an ISO 9001: 2015 company that can provide the most common domestic and international certifications. Ex: cCSAus, UL, IEC, ATEX, ASME, PED, INMETRO.