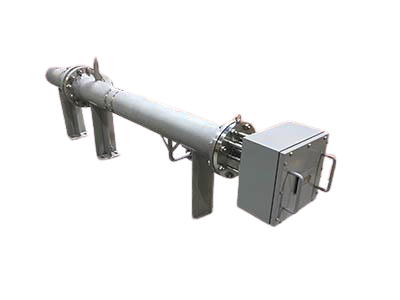

Flow Process Heaters

Low Flow and High Delta T heaters are often linked together. Processes often have one or both of these parameters which has led to a new Patent Pending design for HC Thermal. Why are low flow/high delta heaters so special? With low flow internal vessel velocities at or near laminar cause very poor heat transfer and elevated element temperatures. Combined with a high process Delta T, it puts normal heater elements operating at their limits and often pushes vessel temps into high temp and or exotic alloys. Either of which is detrimental from either budgetary or area location constrictions. Often traditional heater design would have to be stacked in varied watt density design and vessel diameters to be able to achieve the desired process design.

More About This Product

HC Thermal’s Multipass industrial heat exchanger design is a tuneable electric heater that allows for very tight temperature control and very precise element temperature control. This design can be used for gas and liquid applications and houses the solution in a single vessel. Most designs can stay in carbon steel and stainless is an option. Because of the patent-pending design there is no need for H grade vessel materials in the design.

Applications

Superheated Steam, Nitrogen and other gases, high temperature liquid heating close to boiling or coking points.

Advantages

HC Thermal’s designs are compact and can be disassembled for easy cleaning. Easily tailored to customer requirements. No H grade or exotic alloys.

Types/Specifications

1kw to 800kw

240v to 600v

Liquid/Dust tight to Hazardous Area Classifications